Kees vd Westen Speedster

THE ULTIMATE SINGLE GROUP ESPRESSO MACHINE PROVIDING EXTREME PRECISION & MAXIMUM CONTROL IN A SPEEDY PACKAGE

Fixpresso Team

What do you receive?

Overview

SEPARATE BOILERS

The Speedster is equipped with two separately functioning boilers: one large steam boiler to produce hot water and steam, one boiler with group to heat water to brew coffee. Each boiler has its own electronic temperature controller system, heating element and safety devices, offering extremely precise temperature stability.

High capacity is secured by the large steam boiler, over-rated heating elements in both boilers, and a heat-exchanger inside the steam boiler, pre-heating the brew water for the large dedicated coffee boiler.

STEAM BOILER

The rear steam boiler has a total capacity of 3.5 litre. It is made entirely in 316L stainless steel. Wall of boiler is 2mm thick, the flanges are 6mm. An electronic temperature controller gets its information through a very precise and fast reacting probe, located in the steam and activates the heating elements via solid state relays.

The display is installed at the front of the machine. It is easy to adjust and offers an Eco mode for longer periods of idle, dropping temperature to 70 C. The heating elements provide a powerful 1.800Watt. This is divided over two elements of 900Watt each, mounted on one flange. There are no moving parts in the heating system. The steam valve has a large knob, stainless steel wand and a steam tip with 4 holes in fan-shape, each with a diameter of 1,2mm.

Activation of the hot water is done by a switch. The valve body on the machine provides a connection between inner tube and outside wand, visually symmetric to the steam valve.

Two different hot water temperatures can be supplied by one toggle switch. Inside the machine hot water running from the steam/hot water boiler towards the hot water valve is directed first through a mix manifold. On this manifold 2 solenoid valves are installed, one for hot, one for cold water. The cold water flow is restricted by a jet. Pushing downwards the long lever toggle switch activates both solenoid valves and the pump, resulting in a quiet flow of hot water with a temperature below boiling point. When the lever of the toggle switch is pulled upwards, only the hot water solenoid is activated. This results in hot boiling water flowing directly from the boiler to the wand.

BOILER

The coffee water boiler is made in 3mm stainless steel tube and 6mm thick flanges. There is a large hole on top of the coffee water boiler over which the group is installed. The group is made in 4 and 5mm stainless steel. All stainless is 316L. The group head is welded to the group neck, the group neck in turn is welded to the boiler. All welding is done both on the outside as well as the inside to prevent possible crevices which would easily start corrosion. The neck of the boiler is situated vertically, with a slight slope, to allow for a proper constant thermo-siphon heat flow inside, reaching the full length and height of the group. Both the cover as well as the bottom of the group are removable, sealed by O-rings. Total capacity of boiler with group is 2.1ltr.

The cold water entering the machine is first directed through a heat-exchanger located inside the steam boiler. Exiting the heat-exchanger its temperature is higher than needed because the steam boiler runs at 135 degrees C. It is cooled down by flow-crossing the outgoing hot water with the incoming cold water.

At entering the coffee boiler the water first travels through an internal tube over the entire length of the boiler to accommodate quickly to the temperature present inside the coffee water boiler.

The temperature of the coffee water is measured and controlled by a highly sensitive probe connected to a PID (proportional-integral-derivative) controller. This is a control loop feed-back mechanism. A nearly intelligent system, responding ahead, steering the 900Watt heating element by pulses through a solid state relay. There is no moving part in the entire heating and controlling system. This set-up ensures an extremely fast reacting system as well as a very reliable one. The water temperature can easily be changed by just pushing a button at the front of the machine. It is adjustable to 0.1 degrees Celsius.

The controller offers an Eco mode, dropping temperature half way during longer periods of idle.

GROUP

At first installation it is important all air is bled from the coffee boiler. Air can be compressed, water cannot. When the group lever activates the group solenoid valve and pump for the first time, all air is automatically expelled by the inrush of water because the pick-up tube sits right underneath the group`s cover. This is the highest point in the system.

When the heating system reaches and maintains the perfect desired temperature, the challenge this system poses is to not suffer any variation in temperature until the water hits the coffee grounds. Law of nature demands a thermos-syphon flow will commence. Water heated by the heating element will go up. In the Speedster system this flow continues to the very end of the group head. There it will cool slightly, sink and travel downwards again to the bottom of the boiler. The neck and group are specifically designed to offer ample space allowing the hot and cooler flows to pass each other. The “sweet spot”, the most stable temperature in this system, will develop at its highest point, right underneath the group cover. This is isolated by the thick stainless cover and the Bakelite cover on top.

The pick-up tube is positioned right in that sweet spot, running to the 3-way group solenoid valve. This valve is installed at the lower end of the neck, right above the boiler, a position as hot as possible. The valve itself is entirely made in stainless steel. Brass would soak up just a bit more heat from the water passing through it. Stainless transfers heat ten times less than brass, so is far more isolating.

When brewing, the water never leaves the coffee water boiler/group on its way towards the coffee. It runs via a tube inside the group, starting from directly under the group cover, to the stainless steel three-way solenoid valve. From the solenoid valve it is routed through another tube towards the bottom of the group. Both these tubes run virtually horizontal inside the group neck. This path makes for an extra temperature stabilizing effect.

The stainless steel bottom plate of the group sits at a low position, under the water. This causes its temperature to be below the temperature of the water. Water passing the bottom on its way to the coffee grounds, should not lose any of its heat to the metal bottom, therefore the dispersion block reaches up through the bottom plate. The water directly enters the dispersion block, does not touch the metal. This block is made in a polymer plastic, a fully temperature-neutral material. As this block remains cool, the fats and oils in the coffee do not bake on, effectively keeping it clean for a long time. It consists of two pieces offering a nicely divided dispersion of the water, hold up by 2 screws.

The group screen is hold in place by the surrounding rubber group gasket. To pull out the gasket with screen for controlling, cleaning or replacing, a special tool is provided with each machine in the Barista Kit. The rubber gasket ring sits against the bottom of the group. At the bottom of the group a small outward ridge is machined. This ridge is pushed into the rubber gasket each time the filter holder is locked into the group, as an extra sealing surface. The slight moving up of the gasket ring, because of the flexibility of the rubber, provides an ergonomically correct soft comfortable feel for the barista. Full sealing is achieved without having to pull the filter holder firmly.

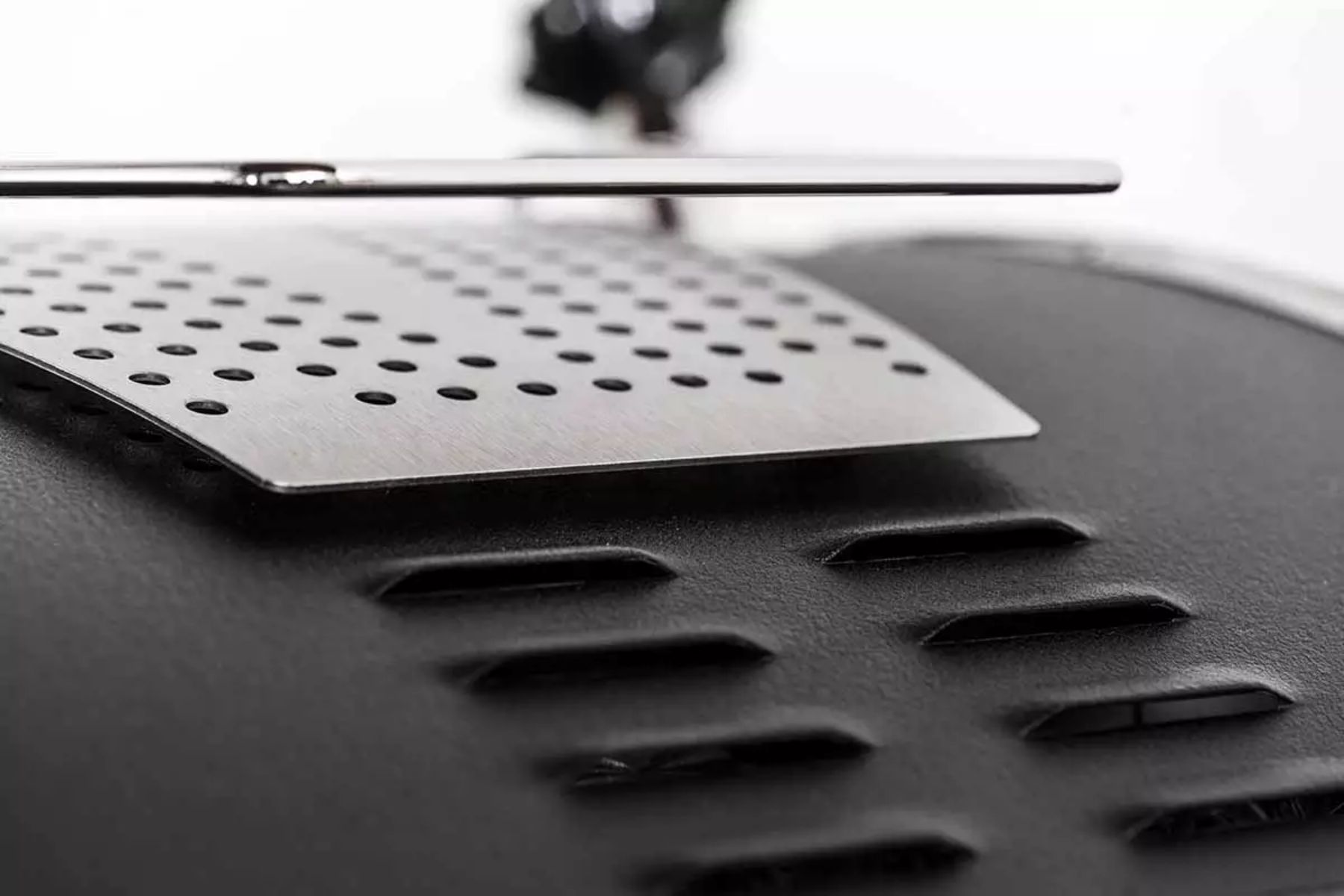

The rubber group gasket is made in a heat resistant material that does not harden and go brittle. It remains flexible. The group screen reaches up and sits against the bottom of the group. This makes it very strong. Together with the rubber gasket surrounding the screen, it is impossible for coffee grounds to ever reach the insides of the group. The supporting horizontal base of the screen is thick to resist deforming. This base is perforated and covered with a stainless steel membrane, not a woven mesh. The membrane provides a very even dispersion of the water during extraction. It also strongly filters the water sucked up when the pressure is discharged at the end of the shot. This again ensures a cleaner inside of the group.

INFUSION

The importance of pre-infusion generally still seems to remain under-estimated. Machines with a slight variation in brewing temperature tend to offer a larger spectrum of different flavours from the coffee grounds. On machines offering a very strict temperature a well-executed pre-infusion becomes imperative, otherwise they might not be able to extract the full range of complexities hidden in the coffee.

Properly infusing the grounds makes for an even wetting and swelling of the grounds. This careful wetting and slow swelling ensure the chance on channelling becomes much smaller. This process also locks in the fines, preventing them from travelling downwards and clogging the filter. Even more importantly however, pre-infusion allows a warming and softening of the fats and oils in the coffee grounds, ahead of the actual extraction with high pressure. This clearly results in a higher yield of solids in the cup. These fats and oils are the carriers of the delicate aromas and flavours.

A good infusion system allows for a finer grind. All the smaller coffee particles together offer a larger surface making it easier to wash out the oils and fats. The brewing lever has three positions. Fully up is off. Halfway offers a manual infusion, the group solenoid is open, pump is not activated. All the way down will start the pump. When the brew process is started by moving the lever all the way down, both the group solenoid valve opens and the pump starts to run.

A 0.6mm jet is positioned ahead of the coffee water boiler, in the tube running from HX to coffee water boiler. The pressure of the pump struggles to pass the tiny 0.6mm jet. At the same time the group solenoid opened, this has an orifice of 1.5mm. As soon as the solenoid opened, water runs through the empty tube from solenoid to coffee, pushed out by the pressure inside the coffee boiler. There is always some pressure inside the coffee boiler, because of the heat. Water reaches the coffee grounds and sinks into the coffee bed. All pressure inside the coffee boiler vanishes, because lots of empty spaces had to be filled: tube, dispersion block and coffee bed. The result is a soft and full saturation of the coffee grounds, with no pressure at all.

Then the pump finally succeeds in pushing enough water through the 0.6mm jet to slowly re-pressurize the complete coffee boiler system. This rising pressure is first absorbed by the spring loaded piston in the pre-infusion cylinder. This is a progressive process as the spring becomes stronger the more it is compressed. The piston`s shaft moves out through the front panel as a visual indication of this infusion process. As soon as the piston hits bottom, pressure will move up to the full 9 bar extraction pressure. This build-up of pressure is steady and slow, ensuring the integrity of the puck remains unaltered.

An additional aspect of the progressive pre-infusion cylinder is some cleaning. After the extraction process is ended, the remaining pressure inside the basket is purged through the internal tube and solenoid, then to the drain. When this pressure has vanished the spring pushes back the piston. All clean water inside the cylinder is forced through the solenoid towards the drain. This rinses the internals of the solenoids. Of course the tube between solenoid and coffee is not flushed, so back-flushing is still needed once in a while.

The pressure gauge is connected to the coffee boiler. This means that as soon as the solenoid valve opens there is one open connection all the way to the coffee puck. The gauge displays the actual extraction pressure, not just the pump pressure. The barista can monitor exactly how infusion and extraction develop. The mid-way position of the lever offers the possibility to play and adjust this procedure at will. As soon as the lever is moved, the steam boiler filling up system is de-activated to prevent any loss in pressure which may damage the extraction process.

SAFETY

The steam boiler has two probes to monitor the level of the water inside. The lower probe is installed just above the heating element. When the machine is fired and filled for the first time, the level controller only switches on all temperature controllers, and thus the heating elements, when the lower probe detects water. During filling up, the coffee boiler fills sooner than the steam boiler because filling starts immediately when the water connection is opened. Also, the coffee boiler is smaller.

When the lower probe in the steam boiler detects water the elements inside the boilers are submerged. This system ensures the elements cannot be turned on while not being cooled by surrounding water. If the steam boiler level would ever fall under the safety probes tip, the machine shuts down completely, controller displays go dark. When the higher probe contacts water the brain de-activates the fill solenoid and pump.

These are activated as soon as the higher probe does not detect water. Both electronic temperature controllers have a restricted upper temperature programmed. When this temperature is reached no more signal to the solid state relay is sent.

Each boiler is equipped with an overheating cut-out switch. When this switch detects too high a temperature, it will disconnect power to the element. The steam boiler is equipped with a safety valve. The coffee boiler system, including the heat-exchanger, is equipped with an expansion valve. The group solenoid valve may act as a second expansion valve, rated at 15 bar, in the event the original expansion valve would fail.

What's included

- Shot timer, installed in full view, right next to group.

- Total consumed power (Watts) can be diminished by retracting an electric bridge at the centre solid state relay: whenever the heating element of the coffee boiler is activated, one of the steam boiler elements is now automatically de-activated. This brings down total wattage with 900 to 2.200Watt. (Standard max wattage is 3.100.) Yet hardly any effect can be noted in capacity. Heating up from cold will take a bit longer however. The bridge on the centre SSR is standard deleted on 115Volt machines.

- Intuitive operation by lever. Group lever offers manual and automatic infusion.

- Self-bleeding group.

- One separate PID temperature controller for each boiler, displays in full easy view.

- Energy saving Eco mode on each temperature controller, for nights and/or weekends.

- Two hot water temperatures under one switch: pulling toggle switch up gives boiling hot water, toggle down supplies mixed cold&hot water.

- Energy saving hot water system. Some cold is added to the hot water, so less heated water is needed. This mix provides a steady, non-spattering stream with the correct temperature to prepare Americanos.

- Drip tray adjustable in height.

- Stainless steel filter holders with KvdW POM handles.

- Slow automatic infusion process, with step-less build-up of pressure to full extraction mode. This allows a finer grind, creating more surface, so a higher yield in the cup, less chance on channeling, preventing fines to travel down.

- Progressive pre-infusion cylinder. Even with the pump running a spring loaded piston absorbs first rising pressure on coffee to allow for a longer initial saturation of the puck.

- Wide choice in filter baskets, both sizes as types.

- Rubber group gaskets remain flexible forever, do not become hard or brittle.

- Membrane type group screen, very nice dispersion, less coffee sucked up by discharge of pressure at end of extraction. Remains clean longer.

- Heat neutral polymer dispersion block, no loss of heat, no baking on of oils and fats, remains clean longer.

- Heavily protected heating element (extra safety level probe, cut-out switches).

- Entire frame in stainless steel only, powder coated in crackle black.

- Large steam boiler capacity of 3.5ltr.

- Large coffee boiler capacity, total of 2.1ltr.